FOR IMMEDIATE RELEASE – LAKE FOREST, CA

Insulectro, the largest distributor of materials for use in the manufacture of PCBs and printed electronics, has announced it will become the exclusive distributor for North America of Arlon copperclad laminates beginning September 4, 2023. Arlon is also the master distributor for Elite Materials Company (EMC) based in Taiwan bringing both product lines to Insulectro.

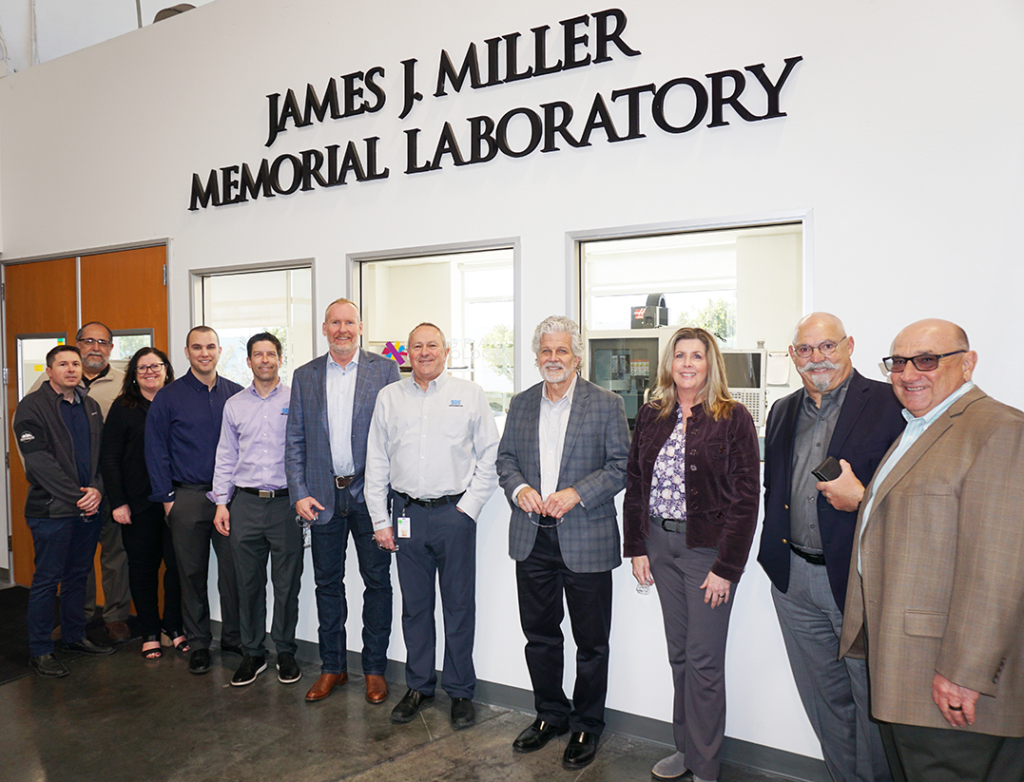

“Today, we welcome two new manufacturers to our World-class supplier/partner family,” announced Insulectro President and CEO Patrick Redfern, “Arlon and EMC offer a wide array of cutting-edge, high-performance laminates for mission critical printed circuit boards manufactured for high endurance and long-life programs. Plus, it allows us to offer California-sourced inventory for greater supply chain reliability.

“This is the beginning of a new era for Insulectro as new materials and relationships strengthen our presence in the PCB industry and prepare us for unprecedented growth. We continually monitor the marketplace to assess challenges and develop solutions. All to enable us to service our customers’ needs today and in the future,” Redfern added.

Arlon was founded in 1969 as Howe Industries and the company manufactured polyimide laminate and prepregs for the printed circuit board industry. Thermoset polyimide resin was the preferred high temperature laminate system known for its thermal stability, good chemical resistance, excellent mechanical properties, and exceptionally good heat resistance. The company evolved to become Arlon Electronic Materials Division after being purchased by Taiwan-based manufacturer EMC in 2020 to establish a base of operations in North America.

EMC was established in 1992 as a dedicated PCB base material manufacturer. Since 2013, EMC has become the largest worldwide manufacturer and supplier of Halogen-free and HDI materials. With a highly skilled Research and Development team, EMC has developed a number of high-speed and high-frequency products, from Mid Loss, Low Loss, Very Low Loss, Ultra Low Loss down to Extreme Low Loss categories. As a result, in 2022, EMC attained the number two worldwide market share position in the specialty laminate (high-speed, high-frequency, and IC substrate) space. These materials are designed for very complex PCBs, such as, for example, Any-layer build-up, mSAP, IC substrate, high layer count (HLC)/ high speed digital (HSD) and radio frequency (RF) products just to name a few.

Following EMC’s acquisition of Arlon, significant investments have been made in the Arlon business to date, with an eye on even greater investment towards continued improvement and expanding the operation in Southern California.

Speaking on behalf of EMC, Chairman Albert Tung commented, “We are pleased to achieve, across North America, logistic and support capability for our customers with this new opportunity with Insulectro. Insulectro has an outstanding reputation as the premier distributor of PCB materials throughout the U.S. and Canada. With this partnership, we have attained our goal of having a solid North America presence, and we aim to continue to expand our product portfolio in North America for years to come. We feel this is an extraordinary opportunity for all three companies.”

Ken Parent, Chief Operating Officer commented, “Arlon’s and EMC’s laminates and prepregs are top shelf materials for fabricators. They will be first-choice selections in such PCB markets as aerospace/defense, aircraft and avionics, automotive, and medical, as well as many industrial applications. We look forward to introducing these products to our customers and OEMs and expect an enthusiastic reception.

“Arlon/EMC’s polyimides, low-flow and epoxy prepregs expand our offerings in rigid, flex, and rigid/flex applications in addition to being compatible with DuPont’s Pyralux® flexible laminates. We expect to be more useful to our existing customers as well as to new customers,” Parent concluded.

Insulectro supplies advanced engineered materials manufactured by DuPont®, Arlon, EMC, LCOA®, CAC, Inc., Pacothane, FOCUSTECH™, JX Metals Corporation, TADCO, EMD Electronics (Ormet®), Shikoku, Denkai America, ETI, Industrial Brush Corporation, Kyocera SGS Precision Tools, InduBond®, and Shur-loc. These products are used by its customers to fabricate complex, multilayer circuit boards and to manufacture printed electronics components. Insulectro serves a broad customer base manufacturing rigid, rigid/flex, and flexible circuit boards for applications in a variety of end markets including aeronautics, telecom, data communications, high speed computing, mobile devices, military, and medical. Insulectro combines its premier product offering with local inventory across North America, fabrication capabilities and backed up by expert customer and technical support services.

Explore Arlon’s Supplier Page Here: ARLON ELECTRONIC MATERIALS – Insulectro

Explore EMC’s Supplier Page Here: EMC (ELITE MATERIALS COMPANY) – Insulectro

For more information, contact:

John A. Lee

Vice President of Marketing & Brand Strategy Insulectro

[email protected]

949.587.3326