CAC® & CSC™

CAC® & CSC™

CAC, Inc. is the manufacturer of CAC® (Copper Aluminum Copper) and CSC™ (Copper Steel Copper).

Its licensed and patented product is domestically produced in a clean room environment to your specifications.

CAC

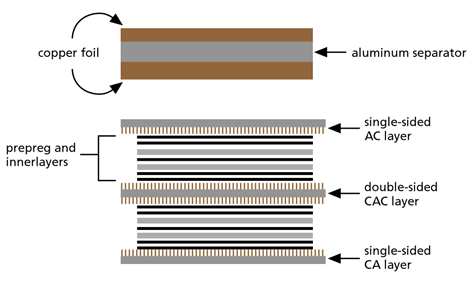

A bonded Aluminum product in Top and Bottom and or middle configuration, with a single layer of your desired copper foil bonded to the aluminum carrier.

- Improved panel flatness – Aluminum CTE is greater than Copper and prepreg resins ensuring a wrinkle free surface

- Achieve Layup Efficiency – No separators to clean resurface or polish which are labor intensive & costly

- Increase quality assurance – Image impressions & FOD concerns minimized with all 4 edges being bonded

- Production Efficiency – Gained by reducing the overall book mass to heat AND cool in a cycle

- Technical enabler – Supporting thin & low-profile Copper foils from 6 µm > with a VLP2 or IPC A profile

With CAC Layup

Without CAC Layup

CSC

A bonded Steel product in Top and Bottom and or middle configuration, with a single layer of your chosen copper foil bonded to the steel carrier.

- 8 mil steel >2x as effective than 15 mil alum in Image transfer reduction / elimination

- Reduce lamination press mass by using CSC, improving heat RoR & Cool down efficiency

- Increased throughput with CSC 8 mil middles, 7.5 times thinner than conventional separators

- Technical enabler – Supporting thin & low-profile Cu foils from 6 µm > with a VLP2 or IPC A profile

- Layup Efficiency – No separators to clean resurface or polish – labor intensive & costly and source of FOD

Supporting Documents

A bonded Aluminum product in Top and Bottom and or middle configuration, with a single layer of your desired copper foil bonded to the aluminum carrier.

A bonded Steel product in Top and Bottom and or middle configuration, with a single layer of your desired copper foil bonded to the steel carrier.