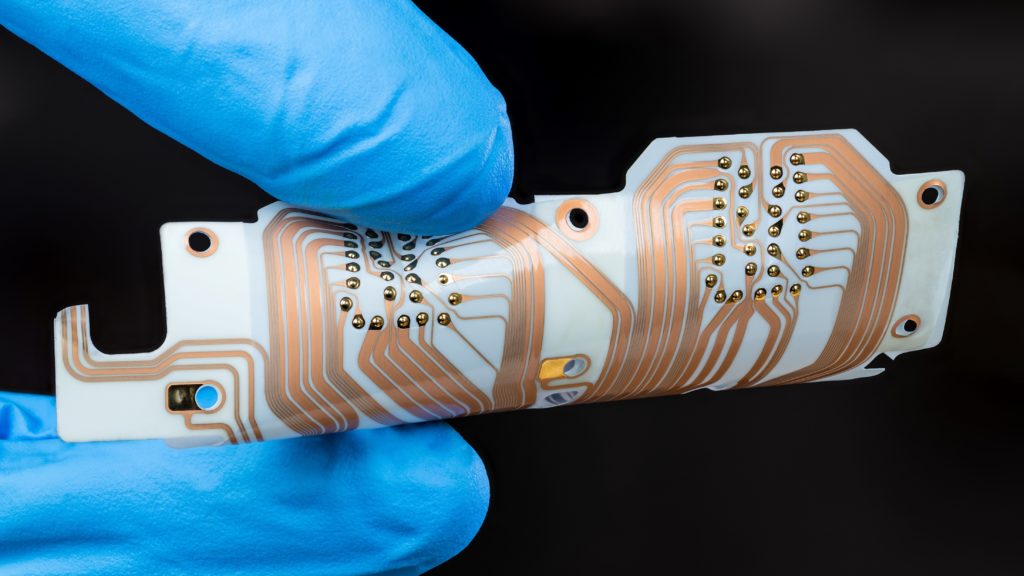

Flexible circuitry

Insulectro, the largest distributor of Flexible substrates for the North American market, proudly distributes DuPont’s complete line of Pyralux® goods.

About Flexible circuitry

Pyralux® materials are the industry standard for fabricating simple single-sided flex to complex multi-layer rigid boards. DuPont’s proprietary formulations of polyimides (Kapton®) have no equal.

From high-reliability designs to simple consumer goods, Pyralux® materials are every designer’s go-to.

custom services

PumaFast™ materials are readily in stock and available for immediate delivery. Standard Materials are popular laminates we distribute and most likely in stock.

Toggle Content

Clads

Qualified and proven for all high-reliability market places such as Space, under hood or medical applications for over 30 years.

A more commercially friendly material with unmatched dynamic bending performance.

Adhesives

The original flexible adhesive. Ideal for its high reliability in commercial design applications.

The adhesive of choice for any High-Temperature operation with an MOT of 225°C.

Specialty & Rigid Flex Products

A clad and bondply material constructed with FEP layers to minimize loss for RF based designs.

A clad and bondply material constructed with FEP layers to minimize loss for RF based designs.

Arlon’s 37N is a 200⁰C glass transition temperature polyimide low-flow resin system designed for bonding multilayer rigid flex, heat sink attachment to MLB’s or other applications where minimal and uniform resin flow is required. 37N can be cured as low as 350⁰F and has excellent thermal stability. Applications include military, aerospace, space, commercial, and industrial PWB electronics.

Meets requirements of IPC-4101/42.

Arlon’s 38N is the second-generation 200⁰C glass transition temperature polyimide low-flow resin system which is designed to improve adhesion and bond strength to Kapton® polyimide films, copper and other metals. Applications include military, aerospace, space, commercial and industrial PWB electronics.

Meets requirements of IPC-4101/42.

Arlon’s 49N is a low-flow epoxy prepreg engineered for bonding multilayer epoxy rigid-flex or attaching heat-sinks to multilayer epoxy PCBs. With a high glass transition temperature of 170⁰C, the prepreg can be used in high-performance or high-temperature applications compared to a standard difunctional epoxy low-flow. 49N is well suited for high-layer count rigid-flex applications where z-axis expansion is a concern.

Meets requirements of IPC-4101/26.

Arlon’s 51N is a non-DICY multifunctional epoxy low-flow prepreg system designed to provide high reliability through lead-free solder operations. The high decomposition temperature and high thermal stability of this material is ideal for use in complex rigid-flex fabrication and assembly operations where minimum resin flow is required.

Meets requirements of IPC-4101/126.

Copper Foils

Ultra-Low Profile Treatment Electro Deposited copper foil with very good ductility for flex applications.

Electro Deposited copper foil with very good ductility for flex applications.

Also known as Rolled Annealed foil is the first choice for flex applications.