conductive inks

Insulectro stocks and distributes Celanese Micromax® conductive inks for a variety of printed electronic applications.

About conductive inks

Celanese Micromax® extensive offering of low-temperature curing inks for flexible substrates enables a variety of advanced printed electronics applications. With an expanding range of new, innovative products targeted to critical customer applications, Celanese Micromax® is driving the future of Printed Electronics.

custom services

- Online Ordering via eCommerce

- Manufacturing Technical Support

- Designer Support

Conductive Inks by Application

A wide range of conductive and dielectric pastes and inks used across virtually all MTS applications from very highly conductive pure silver to low-cost carbon, copper, and alloy conductors.

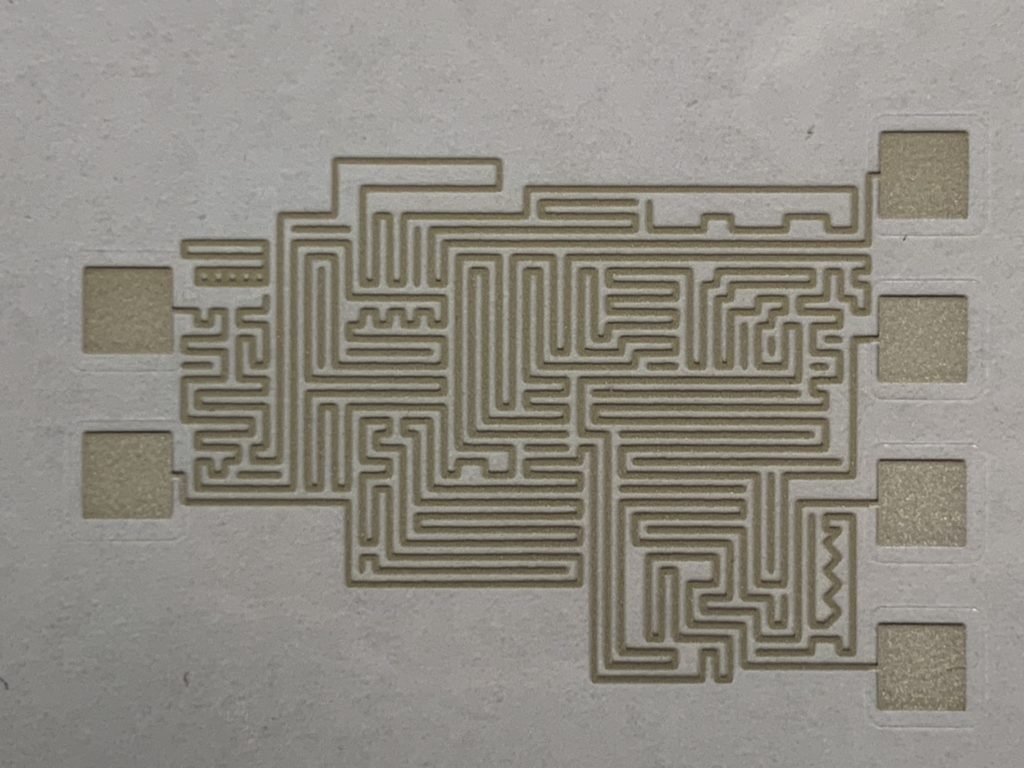

Sensor applications range from biomedical devices to touch sensing, forced sensing as well as thermal sensing products. Sensors are a fast-growing segment of the market as the number of applications for IoT-connected sensors is exploding.

Additive inks help you interact directly with the display through touch. Similarly, in Smart Glass applications, polymer or glass panels are typically ITO (Indium Tin Oxide) or TCO (Transparent Conductive Oxides) coated and addressed with grid lines and bus bars using an additive ink technology.

New copper and silver-coated copper alloy, in addition to all-silver compositions for printing HR and UHR antenna, RFIDs, and smart cards, have been introduced that display excellent conductivity after lamination or photonic curing, ensuring new, cost-effective solutions.

Micromax™ Intexar™ inks are designed to provide numerous elongation cycles with minimal change or hysteresis.

IME Inks are designed to meet the demands of thermoforming when printed onto substrates followed by the extreme environment of injection molding.

Demand for brighter, more efficient LED light sources is challenging solid-state lighting designers. The widespread adoption and use of LEDs have required the use of highly reflective inks along with the need to attach components to existing flexible circuitry with a robust connection not only for conductivity but also for strength and flexibility.

Biomedical inks focus on several areas that range from electrochemical analysis of biological fluids to thermal and biometric sensing. This makes it possible to monitor patients remotely and individuals working in harsh environments to ensure their safety as they perform their tasks in hazardous environments. These inks can also be used on packaging that will function as a smart device reducing the need for external equipment as well as making the package lighter with a significant reduction in cost.

Printed heaters have evolved from traditionally printed resistors with external controllers to self-regulating. Now heaters can be printed with inks that are self-regulating allowing heaters to be designed specifically for the application. This allows for a significant increase in design flexibility by eliminating the need for external control of the printed heating element. Higher temperature heaters can now also be used that exceed 200C for extended periods of time, significantly expanding performance capabilities for designers.

Specialized inks that enable printing on solvent-sensitive substrates that require low-temperature processing. This allows lower-cost substrates such as PVC, ABS, and polyolefins to be used in the manufacture of smart packaging applications.

Products in this area are required to stand up to extreme environments such as solder baths and reflow ovens. These materials need to provide high dielectric strength or superb conductivity while maintaining their performance either on or in a multilayer configuration.

Conductive inks that meet the stringent needs of an engine control module with temperature extremes while providing functional operations in an aesthetically pleasing form such as an interior 3D dash panel.